The mica market size reached around USD 567.57 billion in 2024. The market is projected to grow at a CAGR of 4.30% between 2025 and 2034, reaching nearly USD 864.69 billion by 2034. Mica, a mineral known for its exceptional properties such as heat resistance, electrical insulation, and lightweight texture, plays a pivotal role across a wide range of industries. From cosmetics to electronics, and construction to paints and coatings, the versatility of mica continues to drive its demand in various sectors.

As industries look for more efficient, sustainable, and cost-effective materials, mica’s unique characteristics make it an ideal choice. This blog post explores the key segments of the mica market, highlights the current trends, and discusses the market dynamics that are shaping its future growth.

Market Overview

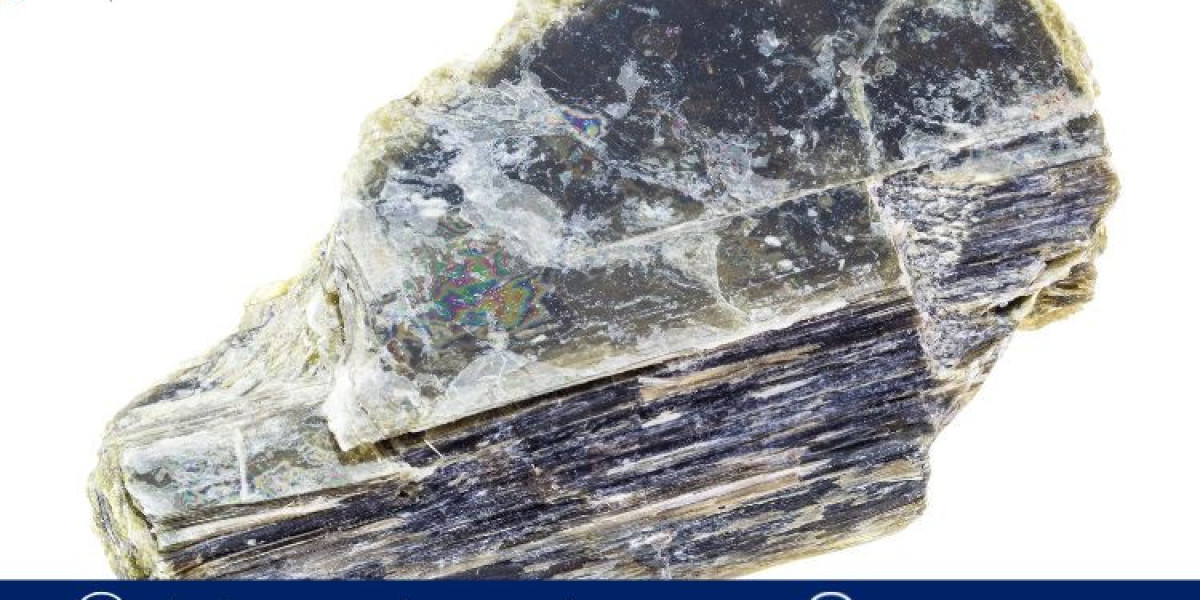

Mica is a group of minerals composed of silicate compounds that are widely used for its heat resistance, electrical insulation, and reflective qualities. It comes in two primary types: natural mica and synthetic mica. Both types of mica serve distinct purposes depending on the industry, with natural mica being more abundant and widely used in cosmetics and construction, while synthetic mica is gaining popularity in high-performance applications such as electronics.

The global mica market's growth is driven by increasing demand in emerging economies, a surge in the popularity of eco-friendly products, and the development of synthetic alternatives. Mica’s usage in various industries, including construction, paints, coatings, electronics, and cosmetics, continues to support its dominance in the global market.

Market Segmentation

By Type

Natural Mica

Natural mica is the most widely used form of mica and is produced by mining mica-rich rocks. It is often available in large sheets and is highly valued for its aesthetic properties and durability. Natural mica is extensively used in cosmetics, particularly in makeup products like eyeshadow and highlighters, where its reflective properties create a shimmering effect. Additionally, it is a key component in paints and coatings, contributing to their durability and texture.

In construction, natural mica is used for insulation and roofing materials due to its heat-resistant properties. Its environmental benefits, being a natural product, further contribute to its growing demand, particularly in sustainable product development.

Synthetic Mica

Synthetic mica is manufactured through a high-temperature process and is typically used in applications that require higher performance levels than natural mica. It has a much higher consistency and purity compared to natural mica, making it ideal for use in electronic components, especially those requiring insulation properties, such as capacitors, resistors, and other electrical devices.

Synthetic mica is also growing in popularity in cosmetics, as it offers better quality control, consistency in size, and reduced impurities compared to its natural counterpart. This makes synthetic mica an attractive option for high-end cosmetic products where consistency and safety are crucial.

By Grade

Ground Mica

Ground mica is a form of processed mica that is finely ground into powder and used in various applications. It is predominantly used in paints and coatings, plastics, and rubber industries, where it helps enhance the texture, increase durability, and add lightweight properties to products. Ground mica is also used as a filler in construction materials such as cement and drywall to improve performance and reduce weight.

The growing demand for environmentally friendly and energy-efficient construction materials has led to an increase in the use of ground mica, as it contributes to the sustainability of construction projects.

Sheet Mica

Sheet mica, one of the most valuable forms of mica, is used in its natural sheet form for applications where its large, thin, and flexible sheets are required. It is widely used in electronics for its insulating properties in high-temperature applications, such as electrical capacitors and heat-resistant devices. Additionally, sheet mica is used in the construction industry for its durability and resistance to wear and tear.

The demand for sheet mica continues to grow due to its essential role in high-performance applications, particularly in industries like electronics and energy.

Built-Up Mica

Built-up mica refers to layers of mica that are bonded together to form a thicker and more durable material. This form of mica is typically used in applications that require high resistance to heat and electrical insulation, such as in the production of machinery components, electrical cables, and industrial equipment.

The growing industrialization of various sectors is expected to drive demand for built-up mica, particularly in machinery and oil and gas applications where high resistance materials are crucial for operational safety and efficiency.

By End-User

Paints and Coatings

Mica is widely used in the paints and coatings industry to improve the performance and appearance of the product. In coatings, mica enhances the texture, durability, and finish, providing a unique visual effect, especially in automotive and industrial coatings. Mica also provides resistance to corrosion, making it an essential material in paints used in harsh environments.

The global demand for paints and coatings, particularly in the automotive, construction, and industrial sectors, is expected to boost the mica market, as more manufacturers incorporate mica into their product formulations to meet consumer demands for high-quality, durable, and aesthetic finishes.

Electronics

Mica’s high heat resistance and electrical insulation properties make it a crucial component in the electronics industry. Mica is used in electronic devices such as capacitors, resistors, and insulators for electrical components, where it helps prevent overheating and short circuits. The increasing demand for electronic products, from consumer electronics to industrial machines, will continue to drive the demand for mica in this sector.

The trend toward smaller, more efficient electronic devices will also contribute to the growing use of synthetic mica, which can provide the required insulation properties while maintaining the compactness and performance of modern electronics.

Construction

In the construction industry, mica is used for its insulating properties in roofing materials, flooring, and insulation products. The rise in the construction of energy-efficient buildings is a key factor driving the demand for mica, as it helps enhance the thermal and electrical performance of building materials. Additionally, mica is used as a filler in concrete and cement products, providing increased strength and reducing the weight of construction materials.

The growing focus on sustainable and energy-efficient construction will continue to benefit the mica market, as more developers seek eco-friendly and high-performance materials.

Cosmetics

Mica is widely used in the cosmetics industry, particularly in makeup products such as eyeshadow, foundation, and highlighter, where it provides a shimmering, radiant effect. The growing trend toward natural and eco-friendly beauty products has contributed to the demand for natural mica, as consumers seek safe, non-toxic ingredients in their cosmetic products.

Mica is also used in skincare formulations to enhance the texture and appearance of creams and lotions. The rise of the “clean beauty” movement will likely further support the growth of mica in the cosmetics sector.

Other Applications

Mica is also used in industries like automotive, pharmaceuticals, and textiles, among others. In the automotive sector, mica is used as a filler in the production of lightweight parts, while in pharmaceuticals, it is used in tablet coatings. The versatile nature of mica ensures that it finds applications in a broad range of industries, contributing to the overall market growth.

Regional Analysis

North America

The North American mica market is primarily driven by demand from the electronics and construction sectors. The U.S. leads the market, with growing applications in electronics, where mica is used for insulation and heat resistance in electronic components. The construction industry’s focus on energy-efficient materials is also fueling demand for mica.

Europe

In Europe, the demand for mica is supported by the paints and coatings industry, particularly in the automotive and industrial sectors. Additionally, European cosmetic companies are increasingly focusing on using natural mica to meet the growing consumer demand for eco-friendly beauty products. Regulatory standards and sustainability initiatives are pushing the mica market in this region toward growth.

Asia-Pacific

The Asia-Pacific region dominates the global mica market, particularly in countries like India and China, where mica is mined in large quantities. The region’s booming construction and electronics industries are major consumers of mica, especially in applications such as insulation and paints. Additionally, increasing awareness of sustainability is driving demand for mica in green construction projects.

Rest of the World

In the rest of the world, particularly in Latin America and the Middle East, the mica market is experiencing growth due to increasing industrialization and the expansion of construction and electronics sectors. These regions are expected to see significant growth over the forecast period, driven by the demand for high-quality and eco-friendly products.

Market Dynamics

SWOT Analysis

- Strengths: Mica’s unique properties, such as heat resistance, electrical insulation, and versatility, make it valuable in many industries.

- Weaknesses: The mica industry faces challenges in sustainable mining practices and fluctuations in supply and demand.

- Opportunities: Growing demand for sustainable and eco-friendly products, increasing use of synthetic mica, and expanding applications in electronics and cosmetics provide significant opportunities.

- Threats: Environmental regulations and competition from alternative materials could pose threats to the mica market.

Porter’s Five Forces Analysis

- Bargaining Power of Suppliers: The mica market faces supply constraints, especially in regions where mica is mined, which could increase suppliers' power.

- Bargaining Power of Buyers: As demand grows, buyers have more options, which may reduce the bargaining power of suppliers.

- Threat of New Entrants: Entry barriers in the mica market are moderate due to the capital investment required for mining and processing.

- Threat of Substitutes: Competition from alternative materials, such as synthetic polymers and glass, poses a moderate threat to the mica market.

- Industry Rivalry: The mica market is competitive, with numerous players focusing on improving production processes and exploring new applications.