AOD (Air-Operated Diaphragm) pumps have gained widespread popularity across various industries due to their unique design and operational efficiency. When coupled with a 50Hz power supply, these pumps deliver optimized performance, making them ideal for a variety of fluid transfer applications. This article delves into the workings of AOD pumps, the advantages of 50Hz power, and why they are a valuable asset in industries like chemical processing, pharmaceuticals, food and beverage, and more.

What Are AOD Pumps?

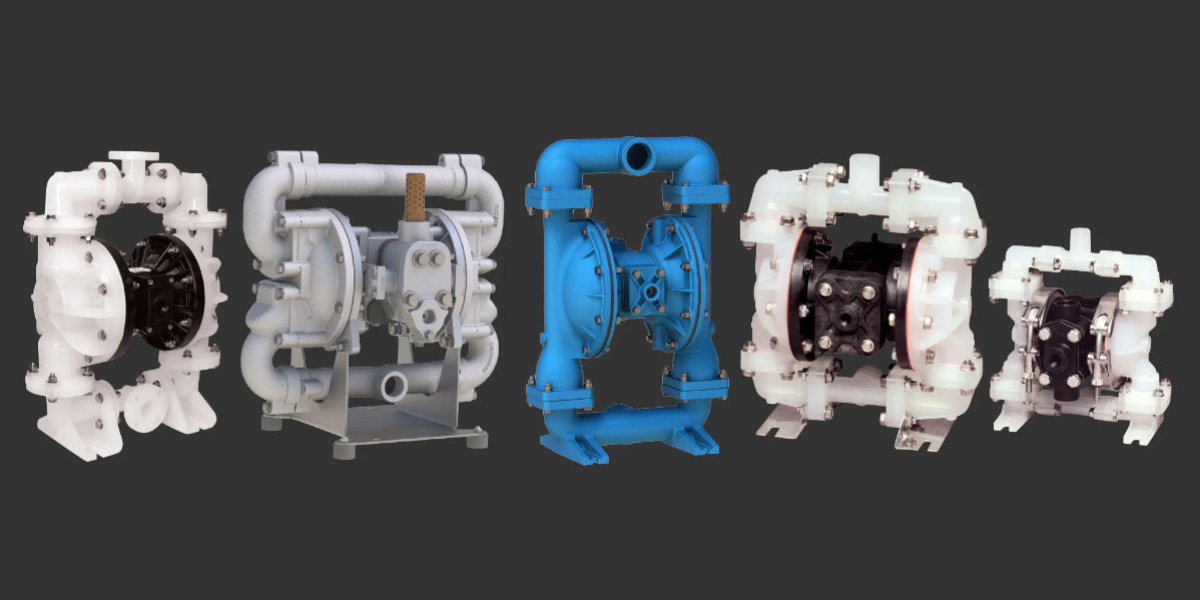

Air-Operated Diaphragm (AOD) pumps are positive displacement pumps driven by compressed air. These pumps use two diaphragms, one on each side of a central chamber, which are alternately pushed and pulled by the air pressure. The reciprocating motion of the diaphragms creates suction and discharge, allowing for the pumping of a wide range of liquids, including viscous, abrasive, and hazardous materials.

One of the key features of AOD pumps is their ability to handle both low and high-flow applications with ease. They are known for their versatility, as they can be used to pump liquids, slurries, and even solids without the need for external power sources like electricity or hydraulic fluids.

The Role of 50Hz Power

In regions where the electrical grid operates on a 50Hz frequency, AOD pumps are often paired with compressors powered by this frequency. The 50Hz power supply impacts the efficiency and operation of these pumps, as it influences the speed of the air compressor that drives the pump’s diaphragm movement.

Consistency and Efficiency: AOD pumps operating on 50Hz power typically offer consistent performance. The 50Hz frequency aligns well with the typical design of AOD pumps, allowing for stable diaphragm motion and ensuring that the pump operates efficiently without fluctuations in pressure or flow rate.

Compatibility with Global Standards: 50Hz is the standard in many countries around the world, particularly in Europe, Asia, and Africa. AOD pumps designed for 50Hz power are optimized for use in these regions, making them highly compatible with existing infrastructure and ensuring that businesses can implement these systems seamlessly.

Energy Efficiency: When paired with 50Hz air compressors, AOD pumps can operate with optimized energy usage. The pumps are capable of maintaining a reliable flow rate while minimizing energy consumption, which can significantly reduce operational costs over time.

Key Benefits of AOD Pumps on 50Hz Systems

Durability and Reliability: AOD pumps are designed for long-term operation, capable of withstanding harsh conditions and demanding environments. Their durable construction ensures that they can handle abrasive, corrosive, and high-viscosity fluids. The reliability of these pumps is further enhanced when running on a stable 50Hz power supply, reducing the likelihood of maintenance issues.

No Need for External Power: One of the most attractive features of AOD pumps is their air-powered operation, eliminating the need for electrical power sources. This makes them highly useful in environments where electricity may not be readily available, or where electrical hazards are a concern. The 50Hz-powered air compressor can supply sufficient power for continuous pump operation without the need for additional energy sources.

Flexibility in Handling Various Fluids: AOD pumps can handle a wide range of fluid types, including chemicals, oils, slurries, food-grade materials, and more. This flexibility makes them ideal for industries such as mining, water treatment, oil and gas, and food processing, where varied liquids and slurries need to be transferred.

Self-Priming and Dry Run Capabilities: AOD pumps are self-priming, meaning they can start pumping without the need for manual priming. Additionally, they can run dry without damage, making them a safe choice in applications where the pump might occasionally lose its fluid supply. This feature is especially valuable when the pump is used in remote areas or where operational conditions are unpredictable.

Applications of AOD Pumps

AOD pumps operating at 50Hz are versatile and can be applied across numerous industries:

Chemical Processing: AOD pumps handle aggressive chemicals and hazardous materials with ease, making them indispensable in chemical manufacturing plants. They are often used for dosing, transfer, and circulation tasks.

Pharmaceuticals: The pharmaceutical industry requires pumps that can handle both high and low-viscosity fluids without contamination. AOD pumps provide a hygienic solution for transferring ingredients, additives, and even thick syrups.

Food and Beverage: AOD pumps are perfect for applications involving the transfer of food-grade liquids such as juices, oils, syrups, and dairy products. The pumps' gentle action ensures minimal damage to the product.

Water and Wastewater Treatment: AOD pumps are widely used in water treatment plants, as they can handle everything from clean water to wastewater with solids and sludge.

Mining and Construction: For transporting slurry and other high-viscosity materials, AOD pumps are reliable, durable, and capable of running efficiently even in remote locations.

Conclusion

AOD pumps 50Hz compressors provide industries with a reliable, efficient, and energy-conscious solution for a variety of fluid transfer needs. Their versatility in handling different liquids, self-priming capabilities, and ability to run dry make them an essential part of modern industrial systems. Whether used in chemical, pharmaceutical, food processing, or other applications, AOD pumps deliver exceptional performance when paired with 50Hz power systems, ensuring both cost-effectiveness and operational continuity.