Modern automation, robotics, and CNC systems demand compact designs with extreme rigidity. This article explains how RU cross roller bearing improves positioning accuracy, simplifies installation, and supports multi-directional loads.

The Problem: Complex Load Handling in Compact Machines

In robotics, rotary tables, and semiconductor equipment, bearings must handle:

Radial loads

Axial loads

Moment loads

At the same time, machines must remain compact and lightweight. Traditional bearing setups often require multiple units, increasing:

Assembly complexity

Alignment difficulty

Installation time

Structural deflection

This reduces system rigidity and long-term stability.

The Solution: What Is an RU Cross Roller Bearing?

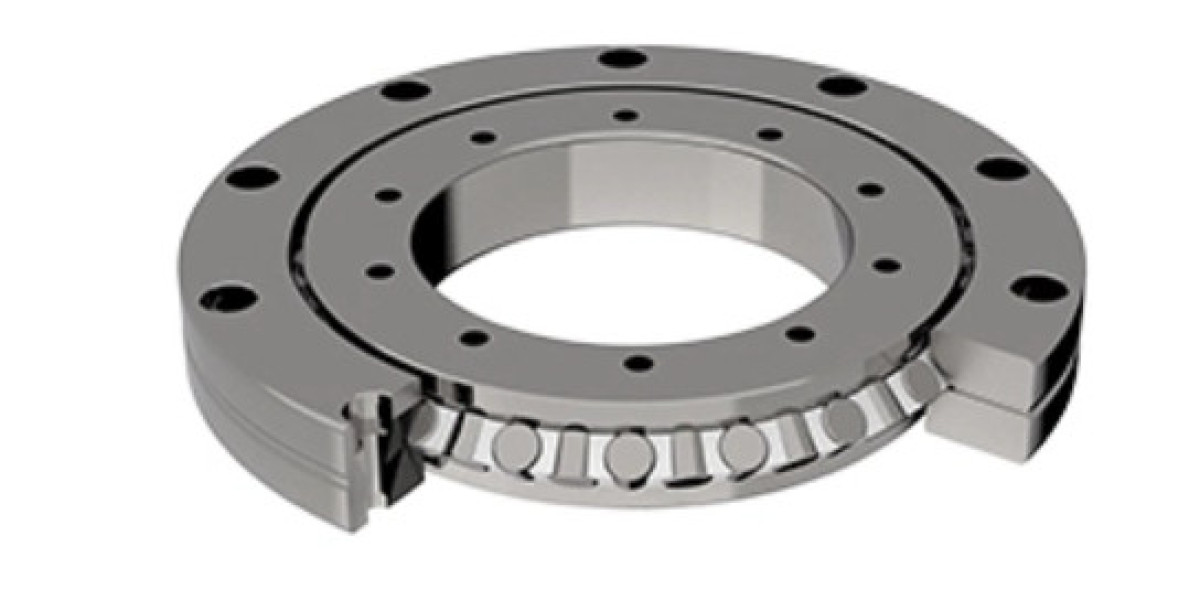

The RU cross roller bearing is an integrated inner and outer ring type bearing designed for high precision and easy installation. Unlike standard cross roller bearings that require separate mounting flanges, the RU type features mounting holes directly on both rings.

You can review detailed specifications of RU cross roller bearing designed for high-performance industrial systems.

How It Works

Inside the bearing:

Cylindrical rollers are arranged at 90-degree angles

Rollers alternately support radial and axial loads

Integrated rings ensure structural rigidity

Even load distribution minimizes deformation

This design allows one bearing to manage complex loads with high stiffness.

Problems with Traditional Bearing Arrangements

Conventional setups often involve:

Two angular contact bearings in combination

Separate housings and shafts

Complicated preload adjustments

Increased mounting errors

These configurations may reduce rigidity and introduce alignment issues, especially in robotic arms and rotary platforms.

How RU Cross Roller Bearing Solves These Challenges

The RU cross roller bearing solves these issues by:

Integrating mounting holes directly into inner and outer rings

Eliminating the need for special housing structures

Reducing installation time

Providing high rotational accuracy

Delivering superior rigidity in compact spaces

Because the rings are integrated, mounting errors are minimized, improving overall system precision.

Key Features Engineers Value

Performance Features

High load capacity in all directions

Excellent rigidity and stiffness

Smooth rotational torque

High positioning accuracy

Structural Advantages

Integrated inner and outer ring design

Compact and space-saving

Easy bolt-on installation

High-quality bearing steel construction

These features make it ideal for precision motion systems.

Comparison Table – RU Type vs Standard Cross Roller Bearing

| Feature | RU Cross Roller Bearing | Standard Cross Roller |

|---|---|---|

| Ring Design | Integrated inner & outer rings | Separate rings |

| Installation | Direct bolt mounting | Requires flange |

| Assembly Complexity | Low | Moderate to High |

| Rigidity | Very High | High |

| Alignment Accuracy | Excellent | Dependent on housing |

| Space Efficiency | Compact | Slightly larger setup |

The RU type simplifies engineering design while maintaining high performance.

Real Industrial Applications

RU cross roller bearing solutions are widely used in:

Industrial robot joints

CNC rotary tables

Precision positioning stages

Semiconductor equipment

Medical imaging systems

Automated inspection devices

In robotics, stable and repeatable motion is critical. Many automation manufacturers rely on RU cross roller bearing designs to achieve compact yet rigid joint structures.

Why Manufacturers Prefer RU Cross Roller Bearings

Manufacturers prefer these bearings because they:

Simplify mechanical design

Reduce installation errors

Increase structural rigidity

Improve repeat positioning accuracy

Lower long-term maintenance costs

The integrated ring structure reduces dependency on external mounting accuracy, making system assembly more reliable.

How to Choose the Right RU Cross Roller Bearing

When selecting a bearing, consider:

Load capacity requirements

Outer and inner diameter dimensions

Required rigidity level

Rotational speed

Mounting bolt pattern compatibility

Environmental operating conditions

For robotics and semiconductor equipment, higher precision grades and preload options are often recommended.

Consulting technical data ensures proper load matching and long service life.

Conclusion

Modern machinery requires compact design without sacrificing rigidity. Traditional multi-bearing systems increase complexity and reduce structural accuracy.

The RU cross roller bearing offers integrated mounting, multi-directional load support, and high rigidity in one compact unit. For engineers and manufacturers, this means:

Simplified installation

Improved positioning precision

Reduced vibration

Greater long-term reliability

Choosing the right bearing technology strengthens system performance and operational stability.