In modern manufacturing, precision, efficiency, and reliability define competitiveness. As production lines grow increasingly intelligent, maintaining airtight system integrity has become essential to ensuring product quality and operational consistency. One critical tool that supports this evolution is the auto vacuum leak detector—a technology that guarantees that sealed components, containers, and assemblies meet strict industry standards. At the forefront of this intelligent transformation stands Guangzhou SANTUO, a company that has been deeply engaged in automatic labeling, machine vision inspection, and intelligent packaging systems for over 20 years.

1. The Role of Auto Vacuum Leak Detectors in Smart Manufacturing

In highly automated environments, even a microscopic leak can compromise product integrity, safety, or shelf life. Auto vacuum leak detectors help manufacturers identify these defects rapidly, ensuring that only fully sealed and compliant products continue down the line.

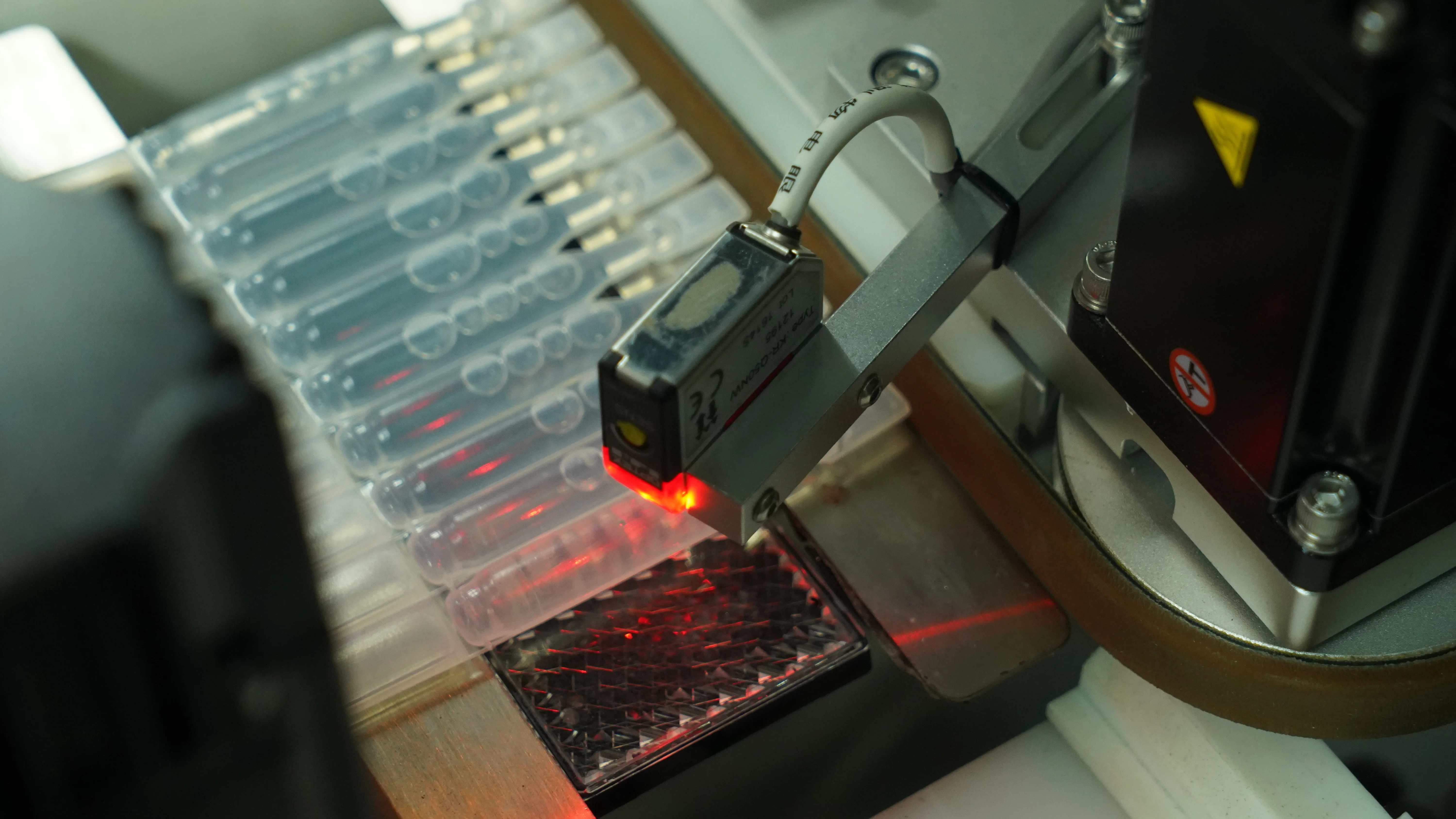

Unlike manual leak detection, which relies on operator experience, an automatic vacuum leak detector provides quantifiable, repeatable, and real-time results. It uses differential pressure monitoring or vacuum decay measurement to detect leaks in containers, pouches, or vials with extreme accuracy—down to micrometer-level deviations.

This precision aligns perfectly with SANTUO’s vision of “replacing manual labor with automation and replacing human eyes with machine vision.” By integrating leak detection systems with vision inspection and robotic packaging, manufacturers can establish closed-loop quality control systems, drastically reducing the probability of undetected defects.

2. How Auto Vacuum Leak Detectors Integrate into SANTUO’s Intelligent Systems

SANTUO integrates mechanical, electrical, software, and vision technologies to create complete intelligent manufacturing solutions. The auto vacuum leak detector serves as a key node in these systems—especially in packaging lines for pharmaceuticals, food, daily chemicals, and chemicals.

For example:

In pharmaceutical packaging, vacuum leak detectors ensure that blister packs, ampoules, and vials remain sterile and sealed, preventing contamination and extending shelf life.

In food and beverage production, they safeguard freshness by detecting leaks in flexible or rigid containers before labeling or final boxing.

In chemical industries, leak detection prevents material loss, safety risks, and downstream contamination.

When integrated with SANTUO’s machine vision inspection modules, these detectors provide automated judgment, sorting, and data traceability, transforming traditional inspection into smart decision-making processes that optimize both yield and safety.

3. Sustainability and Cost Efficiency Through Automation

Leak-free packaging doesn’t just improve quality—it enhances sustainability. Preventing product waste, reducing rework, and extending shelf life directly support eco-friendly goals.

SANTUO’s auto vacuum leak detection solutions combine high testing precision with low energy consumption, minimizing both resource usage and production downtime. This approach aligns with the company’s philosophy of developing “more efficient, more stable, more people-saving, and more energy-saving” automation systems.

In a market where global manufacturers seek smarter and greener production strategies, SANTUO’s integration of leak detection technology provides a tangible competitive edge.

4. The Future of Intelligent Leak Detection

As Industry 4.0 accelerates, auto vacuum leak detectors will evolve further—becoming smaller, faster, and more intelligent. Integration with AI-based analytics, cloud monitoring, and real-time IoT connectivity will enable systems to automatically adjust testing parameters and predict sealing failures before they occur.

SANTUO’s deep expertise in machine vision and intelligent packaging lines positions it as a leader in this transformation. By combining sensor technology, automation, and data-driven control, SANTUO continues to build the foundation for next-generation smart manufacturing ecosystems that drive precision, reliability, and sustainability.

Conclusion

The auto vacuum leak detector represents more than just a testing device—it’s a cornerstone of modern intelligent manufacturing. For industries that demand consistent product integrity and efficiency, integrating automated leak detection is no longer optional; it’s essential.

Through decades of innovation, SANTUO continues to redefine how automation can elevate quality control, proving that when mechanical precision meets intelligent vision, manufacturing reaches its highest potential.