The journey of a plastic product from a digital model to a physical object is facilitated by a critical piece of tooling: the custom plastic injection mould. This engineered device acts as a reusable negative, shaping molten plastic under high pressure into a specific configuration each time the molding cycle is completed. The development of a custom plastic injection mould is a comprehensive process that requires careful planning and collaboration between design and manufacturing teams. The goal is to create a tool that not only accurately forms the part but also does so efficiently, with minimal maintenance and a long service life. The integrity of the final plastic component is directly linked to the quality of the custom plastic injection mould used in its production, making the mould's design and construction phases critically important to the project's overall success.

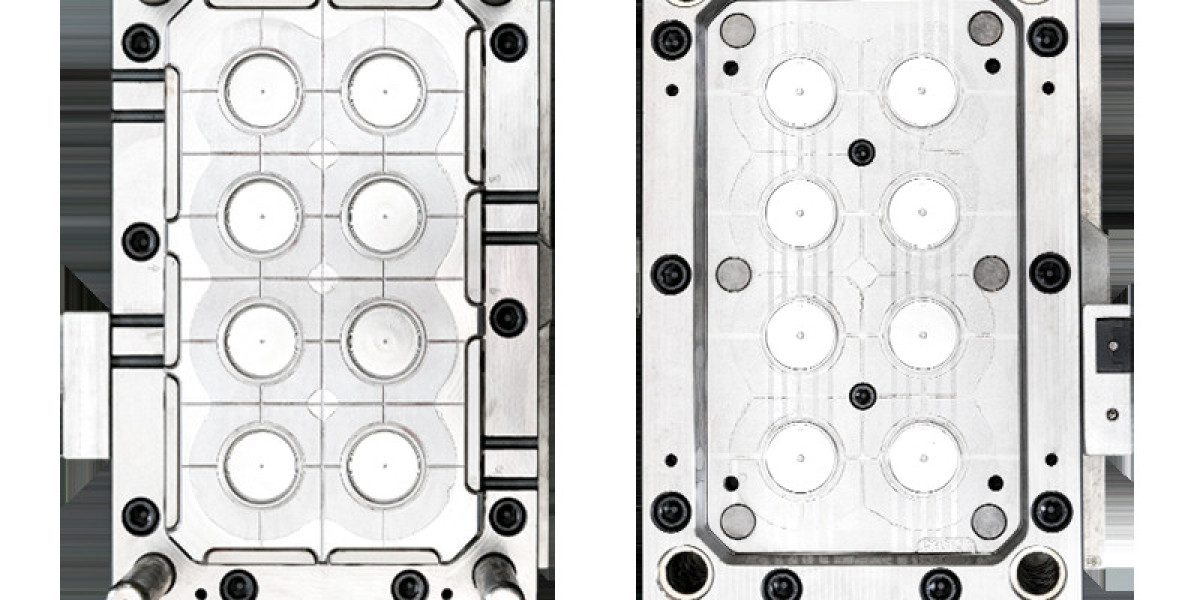

The technical execution of building a custom plastic injection mould involves advanced manufacturing techniques and a thorough knowledge of material science. The process starts with the selection of an appropriate mould steel, chosen for its properties such as hardness, toughness, and resistance to thermal fatigue. The chosen blocks of steel are then meticulously machined. CNC milling creates the general shape of the cavity and core, while more precise methods like EDM are used for finer details and complex geometries. The surface finish of the custom plastic injection mould cavity is achieved through polishing or texturing, which is then imparted onto every part produced. Furthermore, the custom plastic injection mould is equipped with a sophisticated network of internal channels for coolant circulation, which is essential for controlling the cycle time and preventing part deformation. The assembly of all these components into a functioning custom plastic injection mould is a task that demands a high degree of skill and attention to detail.

From a business perspective, the decision to commission a custom plastic injection mould is a strategic move towards securing manufacturing independence and product consistency. Owning a dedicated custom plastic injection mould allows a company to control its production schedule, reduce reliance on external part suppliers, and protect its proprietary designs. The repeatability inherent in the injection molding process, driven by the custom plastic injection mould, ensures that every part from the first to the millionth is virtually identical. This level of consistency is crucial for parts that require assembly, must meet specific regulatory standards, or are part of a strong brand identity where uniformity is expected. The long-term value of a durable custom plastic injection mould makes it a capital asset that contributes to operational stability and predictable product quality over an extended period.

The custom plastic injection mould is a pivotal element in the ecosystem of industrial production, enabling the reliable and efficient mass fabrication of plastic items. Its development is a significant undertaking that merges digital design with physical precision machining. The performance and longevity of a custom plastic injection mould are central to achieving cost-effective manufacturing and maintaining a competitive edge in the market. As product designs become more complex and materials more advanced, the expertise required to produce a high-performance custom plastic injection mould will remain a valuable and sought-after discipline in the manufacturing sector.