Lapping and couplers are two common methods for connecting reinforcing steel bars (rebars) in construction, but they differ drastically in working principles, performance, and application scenarios. While both aim to ensure structural integrity by transferring loads between rebars, their distinct designs and installation processes make them suitable for different project needs. Below is a detailed breakdown of their key differences.

1. Core Difference: Working Principle & Connection Mechanism

The fundamental distinction lies in how each method achieves a stable rebar connection, directly impacting load transfer efficiency.

- Lapping: A traditional, mechanical connection that relies on overlapping rebar segments and the bond between concrete and rebars. Two rebars are overlapped by a specified length (determined by structural codes), then embedded in concrete. The concrete grips the overlapping rebars, transferring stress between them indirectly through the surrounding material. No additional hardware is needed for the connection itself.

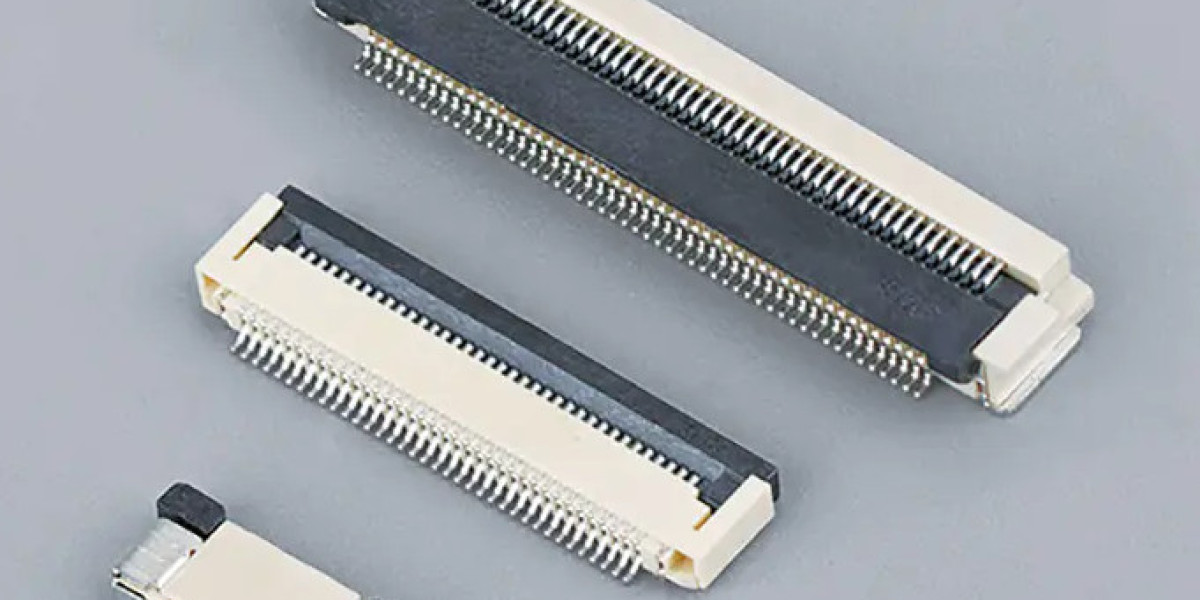

- Couplers: A modern, hardware-based connection that uses specialized sleeves to join rebars directly. The coupler (a metal sleeve with internal threads or a friction-fit design) is attached to the ends of two rebars—either via threading, crimping, or grouting. Loads are transferred directly between the rebars through the coupler, without relying on concrete bonding.

2. Installation Requirements & Space Needs

Their connection mechanisms lead to significant differences in installation complexity and space consumption, critical for tight or high-rise construction.

- Lapping: Requires a long overlap length (often 30–50 times the rebar diameter, e.g., 600mm for 20mm-diameter rebars). This increases the volume of concrete needed to cover the overlap and demands more vertical/horizontal space. Installation is relatively simple (only requiring proper alignment) but time-consuming for large-diameter rebars.

- Couplers: Needs minimal space—only the length of the coupler sleeve (typically 50–100mm) is added to the rebar length. Installation requires precision (e.g., aligning threads or ensuring proper crimping) but is faster, especially in confined spaces (e.g., beam-column joints, high-rise shear walls) where lapping’s long overlap is impractical.

3. Load-Bearing Capacity & Structural Reliability

The direct vs. indirect load transfer affects their strength and consistency, which is vital for structural safety.

- Lapping: Load capacity depends on concrete quality (e.g., compressive strength) and rebar surface texture (to enhance bonding). It may have inconsistent performance if concrete is poorly poured or the overlap length is insufficient. Additionally, lapped connections are weaker in tension compared to the rebar itself, requiring overdesign in high-tension areas.

- Couplers: Offers higher and more consistent load capacity. High-quality couplers (e.g., thread-rolled or friction-welded types) can match or exceed the tensile strength of the rebars, ensuring uniform stress transfer. Their performance is less affected by concrete conditions, making them more reliable for critical structures (e.g., bridges, nuclear power plants).

4. Cost & Application Scenarios

Cost and project requirements further distinguish their use cases in construction projects.

- Lapping: Lower upfront cost (no coupler hardware) but higher long-term costs due to extra rebar material (for the overlap) and increased concrete volume. It is suitable for low-rise buildings, non-critical structural members, or projects with ample space and relaxed strength demands.

- Couplers: Higher upfront cost (for the coupler hardware) but lower overall costs by reducing rebar waste and concrete usage. It is ideal for high-rise buildings, prefabricated structures, tight spaces, or projects requiring high load capacity and structural precision.

For construction projects demanding reliable, space-saving, and high-strength rebar connections—such as high-rises, bridges, or prefabricated structures—Chongqing Huigong’s rebar couplers are an excellent choice, as they ensure consistent load transfer and simplify installation in complex construction scenarios.