Vietnam Smart Manufacturing Market Overview

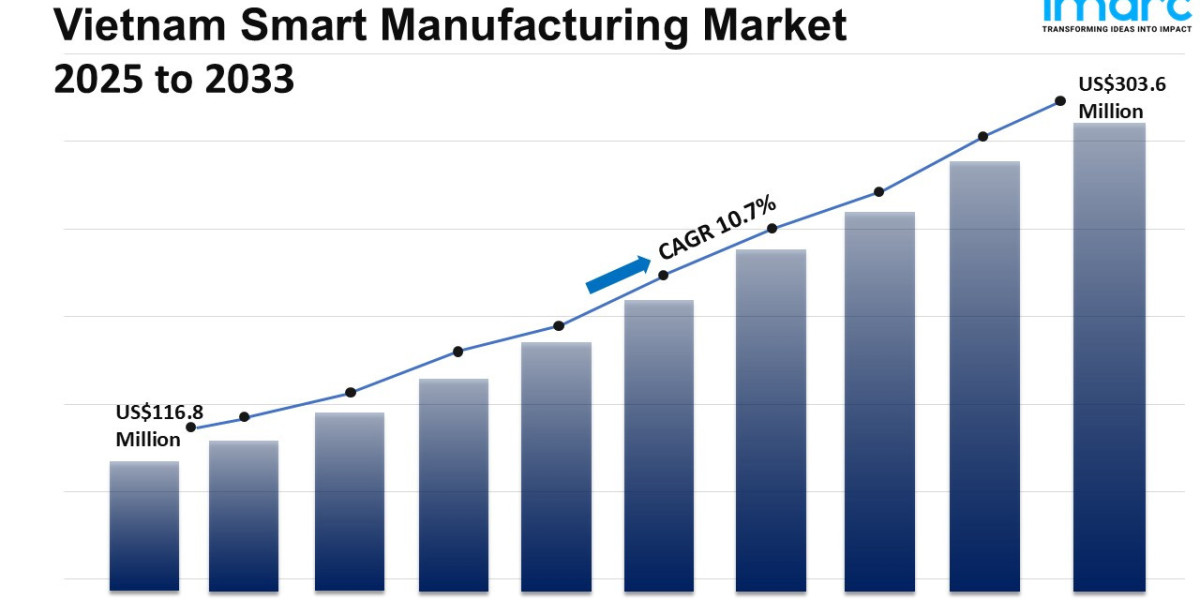

Base Year: 2024

Historical Years: 2019-2024

Forecast Years: 2025-2033

Market Size in 2024:USD 116.8 Billion

Market Forecast in 2033: USD 303.6 Billion

Market Growth Rate (2025-33): 10.7%

The Vietnam smart manufacturing market size reached USD 116.8 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 303.6 Billion by 2033, exhibiting a growth rate (CAGR) of 10.7% during 2025-2033. The increasing labor costs across the region, several technological advancements in automation, artificial intelligence (AI), and the Internet of Things (IoT), and the implementation of several initiatives such as incentives, tax breaks, and subsidies to create a favorable environment represent some of the key factors driving the market.

For an in-depth analysis, you can refer sample copy of the report: https://www.imarcgroup.com/vietnam-smart-manufacturing-market/requestsample

Vietnam Smart Manufacturing Market Trends and Drivers:

Vietnam is actively transforming its industrial landscape, decisively integrating smart manufacturing technologies to enhance productivity, quality, and global competitiveness. This strategic shift is being propelled by a potent combination of robust government support through initiatives like the National Digital Transformation Program and significant foreign direct investment, particularly within high-tech sectors such as electronics, textiles, and automotive components. Multinational corporations are increasingly establishing and upgrading facilities within the country, recognizing its strategic location within Southeast Asia and its maturing supply chain ecosystem. Simultaneously, a burgeoning domestic industrial base is recognizing the imperative to modernize, seeking solutions that streamline operations and reduce reliance on manual labor amidst evolving workforce dynamics. The nation's strong digital infrastructure development, including improving internet connectivity and cloud service adoption, is providing a crucial foundation for deploying sophisticated industrial automation and data analytics platforms. This concerted effort positions Vietnam not merely as a low-cost manufacturing hub but as an increasingly sophisticated player in the global value chain, leveraging technology to create higher-value outputs and foster sustainable industrial growth across diverse sectors.

The adoption of core Industry 4.0 pillars is accelerating rapidly across Vietnamese factories, fundamentally altering production methodologies and operational visibility. Enterprises are implementing interconnected systems where sensors continuously gather machine performance data, feeding into centralized platforms that enable real-time monitoring and predictive maintenance, significantly minimizing costly unplanned downtime. Sophisticated robotics and collaborative automation solutions are becoming commonplace on assembly lines, handling intricate tasks with precision while improving workplace safety and allowing human workers to focus on more complex, value-added activities. Furthermore, the integration of artificial intelligence and machine learning algorithms is optimizing intricate processes like production scheduling, quality control inspection, and energy consumption management, driving unprecedented levels of efficiency and resource optimization. Cloud-based manufacturing execution systems are facilitating seamless data flow from the shop floor to top management, empowering decision-makers with actionable insights to enhance agility and responsiveness to fluctuating market demands and complex global supply chain requirements, thereby strengthening Vietnam's manufacturing resilience.

Looking forward, the Vietnamese smart manufacturing landscape presents immense, untapped potential, driven by continuous innovation and expanding application horizons. Significant opportunities exist in empowering small and medium-sized enterprises to embrace scalable, affordable digital solutions, democratizing access to the productivity gains enjoyed by larger corporations and fostering widespread sectoral advancement. Emerging technologies like digital twins, which create virtual replicas of physical assets for simulation and optimization, alongside the industrial metaverse, offer revolutionary possibilities for remote collaboration, advanced training, and virtual factory planning, further accelerating adoption curves. The growing emphasis on sustainable manufacturing practices is also synergizing with smart technology deployment, enabling precise monitoring and reduction of energy usage, waste generation, and carbon footprint, aligning industrial growth with environmental responsibility goals increasingly demanded by global partners. As Vietnam continues its dynamic economic development journey, the strategic fusion of advanced manufacturing technologies with a skilled, adaptable workforce is creating a powerful engine for sustained industrial innovation, elevating the nation's position as a critical, technologically advanced manufacturing nexus within the rapidly evolving Asia-Pacific region and global economy.

Vietnam Smart Manufacturing Market Industry Segmentation:

Component Insights:

- Hardware

- Software

- Services

Technology Insights:

- Machine Execution Systems

- Programmable Logic Controller

- Enterprise Resource Planning

- SCADA

- Discrete Control Systems

- Human Machine Interface

- Machine Vision

- 3D Printing

- Product Lifecycle Management

- Plant Asset Management

End Use Insights:

- Automotive

- Aerospace and Defense

- Chemicals and Materials

- Healthcare

- Industrial Equipment

- Electronics

- Food and Agriculture

- Oil and Gas

- Others

Regional Insights:

- Northern Vietnam

- Central Vietnam

- Southern Vietnam

Competitive Landscape:

The competitive landscape of the industry has also been examined along with the profiles of the key players.

Ask Our Expert & Browse Full Report with TOC & List of Figure: https://www.imarcgroup.com/request?type=report&id=19766&flag=C

Key highlights of the Report:

- Market Performance (2019-2024)

- Market Outlook (2025-2033)

- COVID-19 Impact on the Market

- Porter’s Five Forces Analysis

- Strategic Recommendations

- Historical, Current and Future Market Trends

- Market Drivers and Success Factors

- SWOT Analysis

- Structure of the Market

- Value Chain Analysis

- Comprehensive Mapping of the Competitive Landscape

Note: If you need specific information that is not currently within the scope of the report, we can provide it to you as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145