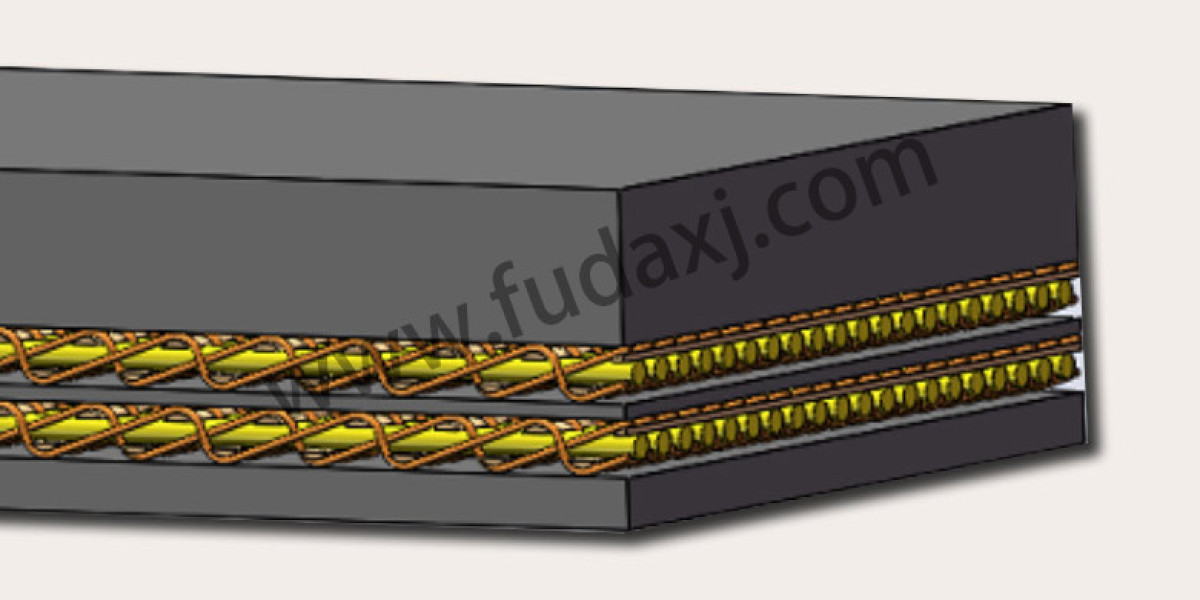

The steel cord conveyor belt is a type of industrial belt used in material handling applications where strength and longevity are required. Constructed with steel cords embedded within rubber layers, the steel cord conveyor belt is engineered to carry heavy loads across long distances with minimal stretch.

In operations such as mining, power generation, and construction, the steel cord conveyor belt plays a key role in transporting materials like ores, coal, and aggregates. Its reinforced design allows it to support significant tension while maintaining smooth and steady movement along the conveyor system.

One of the notable characteristics of the steel cord conveyor belt is its ability to maintain dimensional stability even under high stress. The combination of steel cords and rubber ensures that the belt remains aligned and performs reliably throughout its service life.

The rubber covering of the steel cord conveyor belt offers additional benefits such as resistance to wear and environmental exposure. This protective layer shields the inner cords from moisture, abrasion, and chemical elements, contributing to operational consistency.

Because of its flexible yet robust construction, the steel cord conveyor belt is often selected for applications where other belt types may experience excessive stretching or premature wear. Engineers can tailor the cord layout, rubber composition, and belt width to suit specific usage scenarios.

Overall, the steel cord conveyor belt is a preferred choice for industries requiring consistent transport performance and reduced maintenance. Its mechanical features support demanding operational environments, making it a practical component in various conveyor systems.