In modern manufacturing and logistics, the demand for durable, lightweight, and reusable transportation solutions continues to grow. Among these, plastic pallets have become a reliable choice for many industries. The production of these pallets relies heavily on the design and quality of the plastic pallet mould. A well-designed mould directly influences the efficiency of production lines and the durability of the final product.

One notable advantage of plastic pallet mould technology is its ability to produce consistent and uniform pallet designs. This consistency ensures that every pallet meets required specifications, providing dependable support for goods during storage and transportation. The precision of these moulds reduces the risk of defects and minimizes material waste, contributing to a more sustainable manufacturing process.

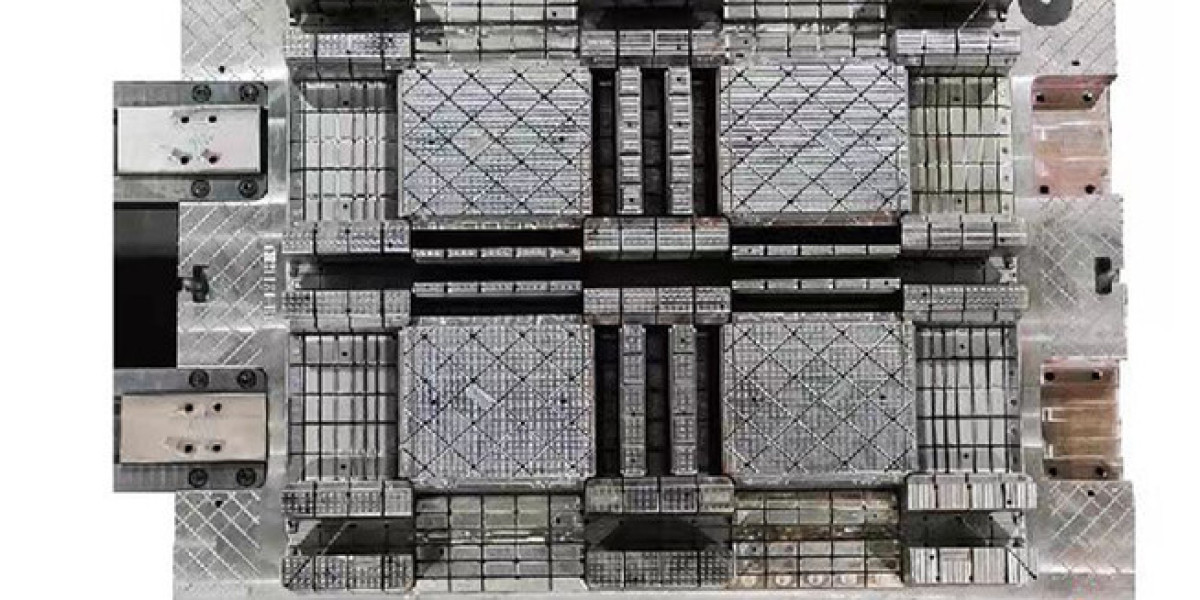

Durability is another important factor. Moulds made from robust materials can withstand the pressure and high temperatures associated with plastic injection molding. This resilience allows manufacturers to maintain long production cycles with minimal interruptions. The strength of the mould also contributes to the quality of the pallets, ensuring that they can handle heavy loads and resist damage from frequent use.

In addition to durability, the flexibility of plastic pallet mould designs is a significant advantage. Manufacturers can create moulds that accommodate various pallet sizes and styles, including double-face, nine-leg, and rackable pallets. This versatility enables companies to meet the specific needs of different industries, such as food processing, pharmaceuticals, and logistics.

Another benefit is the efficiency gained during the production process. Well-engineered moulds are designed for easy demolding, reducing cycle times and increasing output. Features such as smooth surfaces and effective cooling systems help speed up the molding process while maintaining high product quality. As a result, manufacturers can fulfill large-volume orders in a timely and reliable manner.

Furthermore, plastic pallet mould allows for the integration of additional product features, such as reinforced corners, anti-slip surfaces, and nesting capabilities. These enhancements improve the functionality of the pallets, making them more suitable for specific applications and increasing their service life.

Maintenance and longevity are also important considerations. Quality moulds require less frequent repairs and can endure extensive use without significant wear. This reduces operational costs and downtime, ensuring a more consistent production schedule over time.

In conclusion, plastic pallet mould plays an essential role in the production of durable, cost-effective, and versatile pallets for various industrial applications. Its advantages in consistency, durability, flexibility, and production efficiency make it a valuable component in modern manufacturing environments.