In a pivotal stride towards enhancing operational efficiency and ensuring high reliability in diverse industrial applications, two products have emerged as frontrunners in the engineering landscape: the Bellow Seal Globe Valve and Special Alloy Bellows. These solutions, designed with precision and engineered for quality, are poised to redefine industry benchmarks.

Unlocking the Potential: Bellow Seal Globe Valve

The Bellow Seal Globe Valve, a product of ingenuity, is making waves in the fluid control domain. With a design that prioritizes safety, longevity, and leak prevention, this valve has become a good choice for industries demanding meticulous control over fluid flow. The bellows, a key component, seamlessly seals the valve, providing an impermeable barrier against leaks. In critical applications where containment of hazardous substances is important, the Bellow Seal Globe Valve stands as an good guardian.

This valve, equipped with a robust actuation system, offers precise control, ensuring fluid regulation even in hard demanding conditions. The adaptability of the Bellow Seal Globe Valve shines through in industries ranging from petrochemicals to pharmaceuticals, showcasing its versatility and reliability. The valve's rugged construction and minimal maintenance requirements contribute to a seamless integration into various operational setups.

Forging Ahead with Special Alloy Bellows

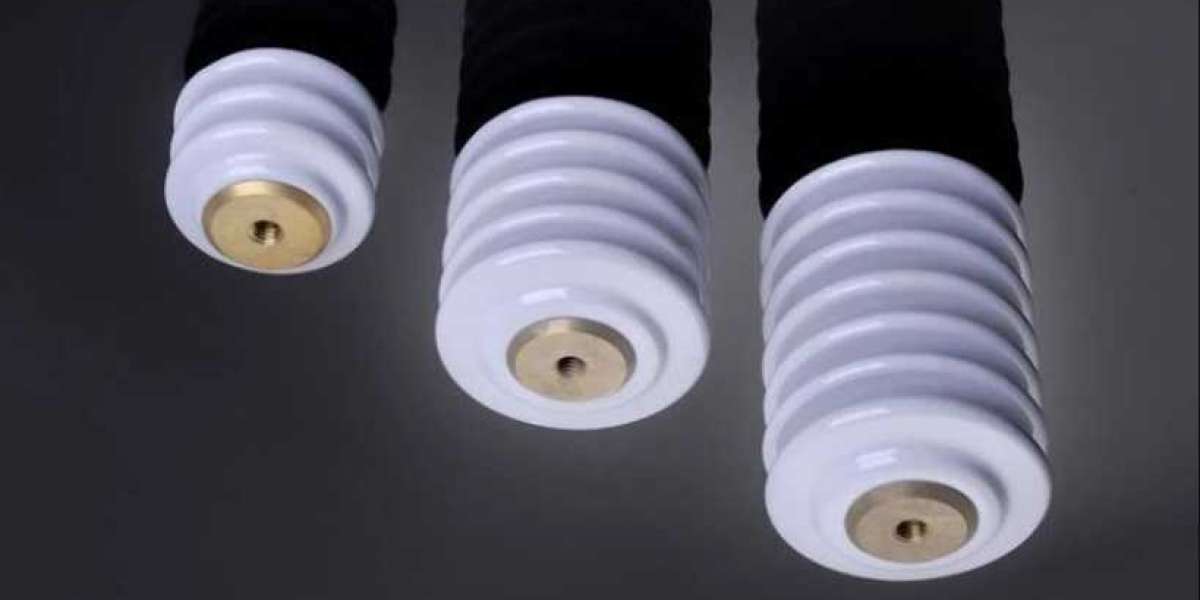

Simultaneously, the realm of industrial engineering is witnessing a transformative shift with the ascendancy of Special Alloy Bellows. These advanced bellows, crafted from specialized alloys, exhibit high durability and resistance to hard conditions. With applications spanning from aerospace to chemical processing, these bellows have become important components in systems where temperature fluctuations, corrosive environments, and high pressures are commonplace.

The Special Alloy Bellows boasts a unique amalgamation of materials that defy the limitations of traditional bellows. This not only ensures longevity but also significantly reduces the risk of corrosion and wear. Industries dealing with volatile substances, such as acids or high-temperature gases, now have a reliable ally in the form of Special Alloy Bellows, ensuring the integrity of their systems over prolonged operational lifespans.

As these two innovations continue to proliferate across industries, their synergistic potential becomes increasingly evident. The integration of Bellow Seal Globe Valves with Special Alloy Bellows amplifies the overall system reliability, creating a harmonious partnership that withstands the hard industrial challenges. The resilience of the Bellow Seal Globe Valve, coupled with the durability of Special Alloy Bellows, provides a robust solution for critical applications where failure is not an option.

In the realm of fluid control, the Bellow Seal Globe Valve's adaptability to evolving industry standards positions it as a cornerstone in the pursuit of precision and reliability. Meanwhile, the Special Alloy Bellows, with its resilience to the hard conditions, promises to be an enduring solution for industries venturing into uncharted territories.

As we navigate the complexities of a rapidly changing industrial landscape, the synergy between these innovations will undoubtedly lead to the creation of more resilient and sophisticated systems. The trajectory ahead is marked by a commitment to innovation, pushing the boundaries of what is achievable, and ensuring that industries can confidently face the challenges that lie ahead.

The advent of the Bellow Seal Globe Valve and Special Alloy Bellows marks a paradigm shift in industrial engineering, setting new benchmarks for performance, safety, and longevity. As industries continue to evolve, these innovations are poised to play a pivotal role in shaping the future of fluid control and containment systems, underlining the commitment to quality and reliability in engineering practices.