When selecting Deep Hole Drilling Tools, it is important to consider several factors that will impact the efficiency, quality, and cost of the drilling process. One of the key factors is the material being drilled. Harder materials like stainless steel or titanium require more robust tools with special coatings to ensure durability and precision. On the other hand, softer materials may require less specialized tools.

Another consideration is the hole diameter and depth. Larger holes or deeper holes will require tools that can manage increased pressures and maintain accuracy. In such cases, double-tube tools or BTA tools are commonly preferred due to their enhanced cooling and chip removal capabilities. For smaller holes, single-tube tools may be sufficient.

Cooling is another critical factor when choosing deep hole drilling tools. Proper coolant flow is essential to prevent overheating and to flush away chips efficiently. Without proper cooling, the drilling process can cause tool wear, inaccuracies, or even tool failure.

Finally, the type of drilling machine available can influence the choice of tool. Some tools are more compatible with specific machines, and matching the tool to the machine can improve overall performance and extend tool life. Understanding these factors will help in selecting the most suitable deep hole drilling tool for specific applications.

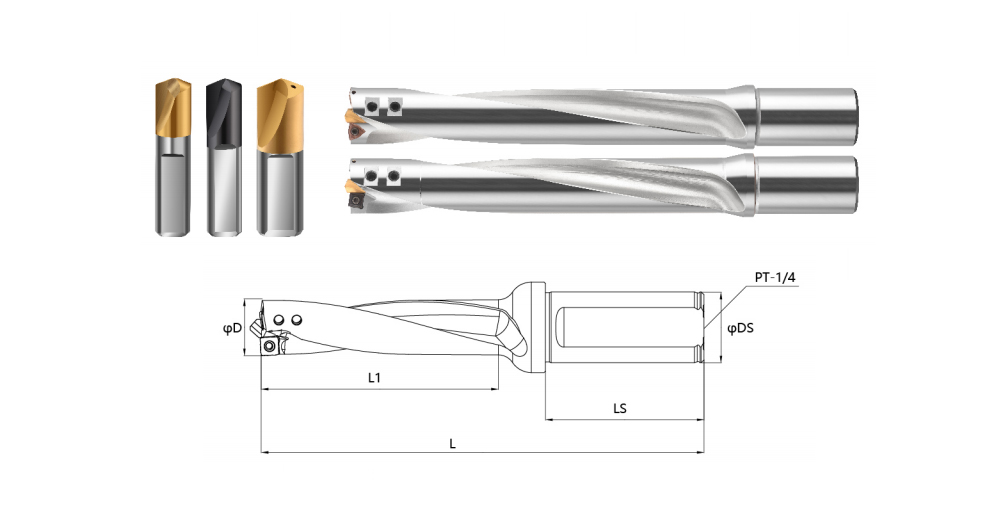

HD-3 8D cutting depth high efficiency self-centering fast drill is a cutting tool designed for efficient machining. It is a fast drill suitable for a depth of cut of 8 diameters (8D), thus enabling efficient machining in deep holes.