Transformer substation manufacturers play a key role in the power distribution process. They design and produce substations that help convert and regulate electrical voltage levels for safe and efficient power delivery. These manufacturers cater to industries such as utilities, renewable energy, and commercial infrastructure, ensuring the smooth operation of electrical networks.

The manufacturing process typically begins with assessing customer needs and technical requirements. This stage involves designing the substation layout, selecting materials, and determining the appropriate transformer specifications. Manufacturers focus on providing solutions that align with industry standards and local regulations.

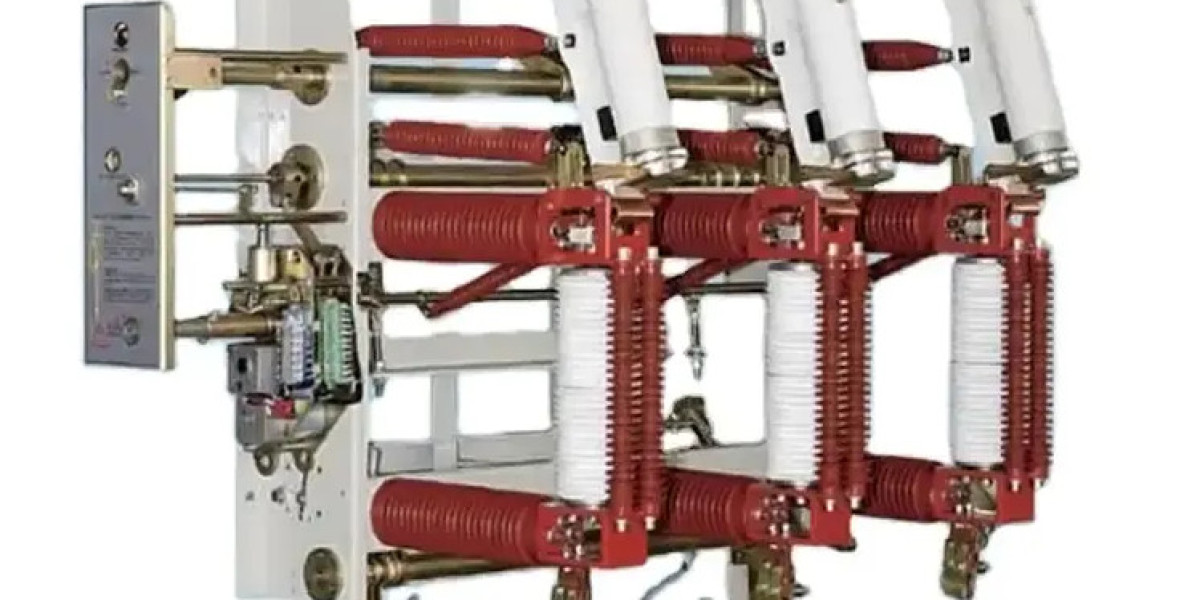

Transformer substation manufacturers also integrate advanced technologies into their designs. These may include automated monitoring systems, temperature control mechanisms, and protective devices that enhance safety and performance. The goal is to provide reliable and durable substations that can withstand environmental factors and operational demands.

Quality control is an essential part of the production process. Manufacturers conduct multiple tests, including insulation resistance, load handling, and thermal performance checks. This ensures the substation meets safety standards and operates efficiently under various conditions.

In addition to production, manufacturers often provide installation support and maintenance services. This helps extend the lifespan of the equipment and ensures consistent performance over time. Transformer substation manufacturers continue to innovate, focusing on energy efficiency, compact designs, and smart grid compatibility to meet evolving industry needs.