As industrial automation advances, Industrial Connector play a crucial role in supporting the transition to smart factories. These connectors facilitate seamless communication between sensors, controllers, and machinery, enabling real-time monitoring and control of production processes.

One of the primary functions of industrial connectors in automation is ensuring stable data transmission. Many automated systems rely on industrial Ethernet and fieldbus communication networks, requiring connectors that provide secure and interference-free connections. Shielded industrial connectors help reduce electromagnetic interference, ensuring accurate data transfer across interconnected devices.

Another significant impact of industrial connectors is their contribution to system scalability. In smart factories, production lines are frequently adjusted to meet changing demands. Modular and reconfigurable industrial connectors allow quick integration of new equipment without the need for extensive wiring modifications. This flexibility improves efficiency and reduces downtime during production adjustments.

Furthermore, industrial connectors enhance workplace safety. By ensuring secure electrical connections, they help prevent short circuits and system failures that could lead to accidents. Some connectors also feature locking mechanisms to prevent unintended disconnections, adding an extra layer of protection for automated operations.

With the continued development of Industry 4.0, industrial connectors will remain a fundamental component in automation, supporting the seamless integration of advanced technologies and improving overall industrial efficiency.

https://www.socketsfe.com/product/

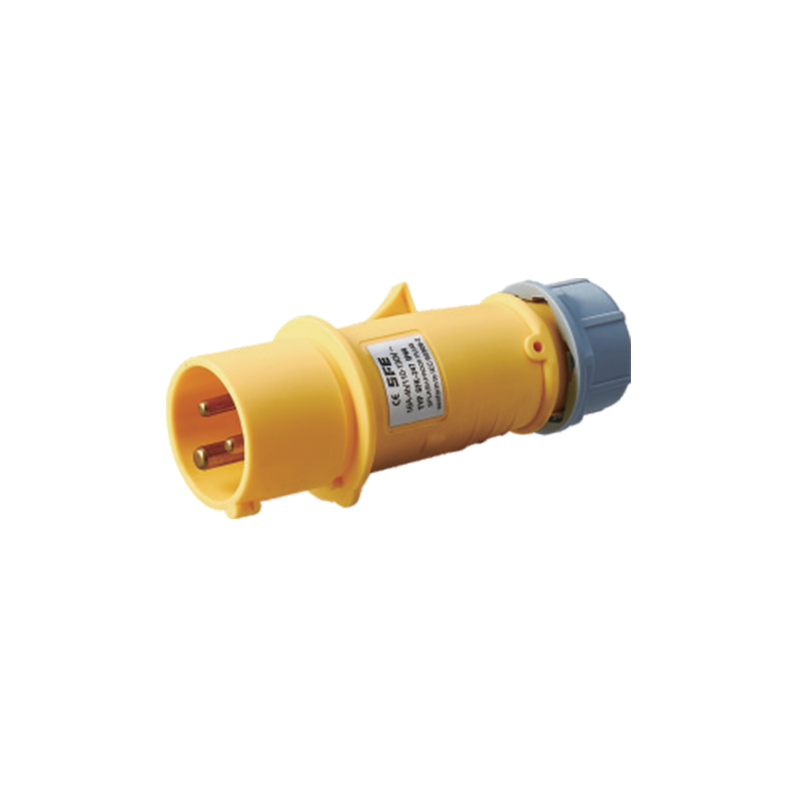

| Current(A): | 16A, 32A |

| Voltage(V): | 110-130V~2P+E |

| Protection degree: | IP44 |